The Numbers That Matter

-

30%

Efficiency Saving

-

240

Hours Saved per Week

-

700+

Suppliers Managed

About Libra Industries

Libra Industries has a long history of producing complex products for the military, aerospace, medical and industrial sectors. A systems integrator, they provide complete manufacturing solutions to a sophisticated client base looking for exceptional client service. Due to the complex nature of what they produce, Libra’s relationships and flow of information from their supply chain is critical. That’s why when Centelli first started speaking to Libra we identified this as an area where a Digital Worker could make a real difference.

Problem

Every order Libra receives requires a complex onward supply chain, summarized for each order in what’s called a ‘Materials Requirement Plan’ (or MRP). Libra’s team of buyers are responsible for managing these various supplier relationships, and yet they were doing this individually, and having to then log all the various information into the Purchase Order system was time-consuming. Plus, even with a committed team, it meant many of these MRPs were incomplete at any point in time – which meant a risk of delays in supply and consequently customer delivery dates! At Centelli, we saw how we could automate supply chain management for the business.

Solution

-

Reduced Costs From staff time updating POs & Materials Requirement Plan.

-

Increased Profitability With buyers able to focus on supplier pricing more.

-

Reduced Risk From errors or gaps in supplier updates & MRP.

-

Happier Customers Happier Customers with fewer production delays.

-

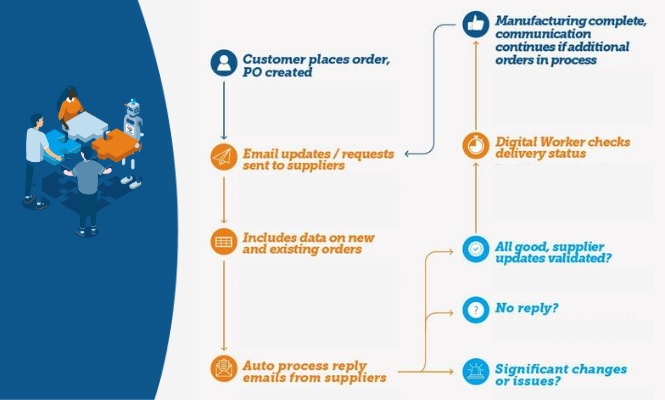

Customer places order, PO created

-

Email updates/requests sent to suppliers

-

Includes data on new and existing orders

-

Auto process reply emails from suppliers

-

Manufacturing complete, communication continues if additional orders in process

-

Digital Worker checks delivery status

-

All good, supplier updates validated?

-

No reply?

-

Significant changes or issues?